We are resurfacing this Mechanical Monday halfway through the cyclocross offseason, the perfect time to make sure your bike has withstood the beating of the Fall and Winter. Questions about carbon fatigue are answered, but the article also examines the maintenance of carbon forks, cutting carbon steerer tubes, and when to examine the fork during the season.

by Jordan Villela

Many of us have been riding a carbon fiber fork on our cyclocross bikes for many years now. We hear of carbon fiber’s almost infinite fatigue life, but we all know that a cyclocross fork sure sees a lot of action out on the course. Does normal cyclocross use and racing give your fork an expiration date?

That question runs through my mind more and more these days, and I decided to talk to the carbon fork manufacturers and see what they had to say regarding fork replacement. I approached experts at Enve Composites, Ritchey, and Whisky Parts Co. to pick their brains about the when to replace a carbon fork, where to look for damage, and why it is so important to check your fork after every spill.

What maintenance should be done with a carbon fork for a ’cross bike?

Jake Pantone (Marketing at Enve Composites): Try to inspect the fork at least once a year around the crown rake and clamp areas for any cracks or grooves. Inspect the dropouts for any chipping or cracking that would look suspect, and obviously [check for] any signs of breakdown or failing.

Sean Coffey (Development and Global Marketing Director at Ritchey, who released their carbon fork with a disc brake since the first publication of this article): Try to make a habit of checking the fork before every race, that way you can catch any problems early.

Eric Wittleder (Technical Support at Whisky Parts Co.): Keep your fork clean… That makes it easier to see any cracks and possible issues.

Any special instructions for cutting the steerer that may prolong the life of the fork?

Coffey: For cutting, use a fresh hacksaw blade and a saw guide, and cut slowly. Make sure to let the blade do the work and not to force the cut. When approaching the end of the cutting process, resist the desire to break the any pieces off before the cut is complete. Make sure to file the edges down to prevent any layers from coming up or getting snagged during the install of the headset and stem.

Wittleder: Make sure to use a carbon fiber hacksaw blade. Most importantly, make sure to measure twice and cut once. You can err on the side of leaving too much steerer tube to get the most life out of the fork. Also, make sure to use a high quality compression plug, and be mindful of manufacture torque specs.

Pantone: A tile saw is the absolute best way to cut a carbon tube. The saw itself is usually priced under $100 and could be a good investment if you are doing lots of carbon steerer tube cutting.

What is a good indicator as to when a carbon fork should be replaced?

Coffey: The fork should be replaced when you see any damage, or a crack found during inspection. Also after a hard crash or if the front end of the bike takes a major hit. And if you are in doubt, best to replace it and not risk it. Fork failures are some of the worst crashes that a person could be in.

Pantone: Any visual damage indicates that it is time to replace the fork.

How should someone visually inspect the fork for damage or wear? Does the inspection change when the steer is alloy?

Coffey: No, no change whether the fork is a carbon or alloy steer. Look for cracks in the clear coat, small spider web-like formations on the paint or in the carbon itself. Make a habit of checking the fork every six months. During the inspection, make sure to take everything off the fork, even the crown rake, if you have the tools. Perform an in-depth visual inspection to ensure that there’s no damage.

Pantone: Make sure to be thorough with your inspections and check over the whole fork.

Regarding alloy steerers, is the bonding between of carbon and alloy durable enough to put up with the demands of years of cyclocross?

Wittleder: Yes, we perform tests upon tests to make sure that our forks are built tough. We also do third party testing, these tests are 5-10% above the normal testing requirements.

Coffey: Sure, bonded joints are on most carbon bikes, even with alloy. The types of bonding employed uses glue that bonds to the same strength as the material that they are bonded to. All of the forks must mass the CEN crash and fatigue tests.

Now that cyclocross bikes are being designed with disc brakes, with full carbon forks, would the braking forces of carbon make the carbon fatigue faster? What rotor size did you design your fork around?

Pantone: Our forks are designed and engineered around disc brake-friendliness. There is very little fatigue to the carbon itself. We design our forks around a 160mm rotor size post mount, and can fit up to a 180mm, but I wouldn’t go any bigger than that.

Wittleder: All carbon has a small amount of flex and the carbon really has no fatigue. Our forks are tested around the 140-160mm rotor size.

Coffey: Braking force is a big factor, and most carbon will take it. A properly designed fork is designed to take a lot of force, and will be reinforced around the key braking features. I can see most manufacturers using 140-160mm as a standard. Since the contact patch is small on cyclocross tires, you wouldn’t need that much force.

With disc brakes, are there any other ways to visually inspect the fork for problems?

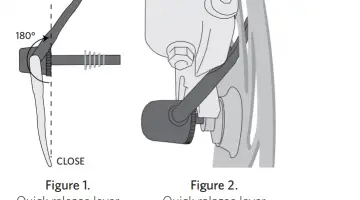

Pantone: Same as any other fork. The only piece that is different is the direct mount piece. The direct mount for the caliper is bonded to alloy threads. I would say to visually inspect those whenever performing a full inspection. The dropouts are different on our disc fork, they face more forward than the other forks we offer. Make sure the front wheel is seated in the dropouts properly. A wheel that is not seated in the dropouts may damage the fork, so make sure the quick release is secured.

Coffey: Use the same procedure you would for any other fork, but pay extra attention to all of the mounting points, and abide to the manufacture torque specs.

Wittleder: Make sure to inspect around any IS tabs and around the direct mount.

Since crashes and falls are so common in cyclocross, what kind of event would warrant a full inspection?

Coffey: Hitting the barriers is the big one. Really, anytime that the front end of the bike goes through a rougher than normal cyclocross experience. Like being in a crash with two or more riders, for example.

Pantone: Anytime that someone has a hard crash. Anytime that there is visual damage to the fork, like scratches. And definitely any harder than normal impact to the front wheel, i.e. hitting a barrier head on.

Wittleder: The fork should be looked over after anytime the bike goes through a wreck.

If a rider races frequently, trains and commutes on the cyclocross bike, and if it passes all visual inspection, when would be a good time be to replace the fork as a form of routine maintenance?

Coffey: Inspection is key, carbon has an amazingly long fatigue life. As long as there are no cracks or suspicious marks on the fork, you should be good to ride.

Wittleder: The fork should be good as long as the fork passes the visual inspections and there are no questionable scratches or grooves.

Pantone: As long as you take care of the fork and keep up with the inspections, it will be good to ride for many years to come.