by Joey Mullan

Remember when you saved your paychecks as a young man for that “child’s toy”: a bicycle? Everyone thought you were crazy spending 500, even up to 1,000 clams for your first two-wheeled wonder machine. But to you, it was the most amazing thing you had ever purchased. And now, you’re still into bikes and cool parts … I know this because you’re reading this review. When you had your bike, you didn’t just ride it, you looked into how you could better it. Anodized, alloy, CNC’d; you wanted something that would set your steed apart from the others. You wanted the best. You had an assortment of companies to choose from. As the years went by, companies closed, trends changed, and many other brands went mainstream. They focused on higher margins and importing parts, and less on good, old fashioned, American craftsmanship. You wanted to have the coolest of the cool.

Now let’s fast-forward a few decades from that first bike purchase. White Industries was born in 1978 and it is still running strong. Owner Doug White proudly engineers, manufactures, and distributes their components out of Petaluma, California. Their parts and philosophy have not changed much through the years. There have been a few cosmetic alterations and additions to their already utilitarian lineup. It is a true testament to their durability, quality, and image the company has made for itself throughout the years.

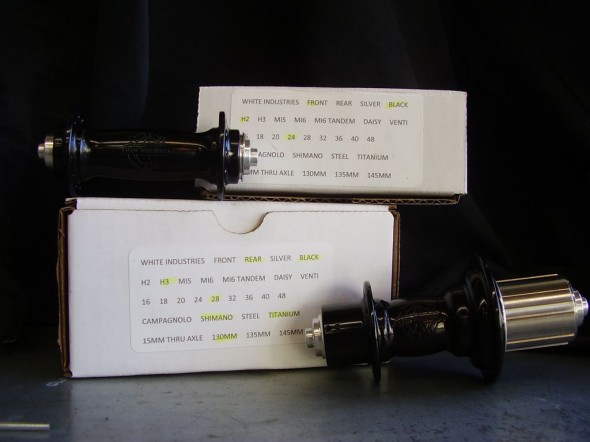

I had the opportunity to try out a set of their H2 and H3 road/cyclocross hubs. The parts were tucked away in corrugated old-school part boxes that had highlighter marks depicting the part, and their respective specs were inside. Underneath the hubs were what looked to be hand-typed pieces of paper. They showed exploded views, overhaul manuals, and hub dimensions – anything necessary for when you lace up your rims and maintain your new hubs.

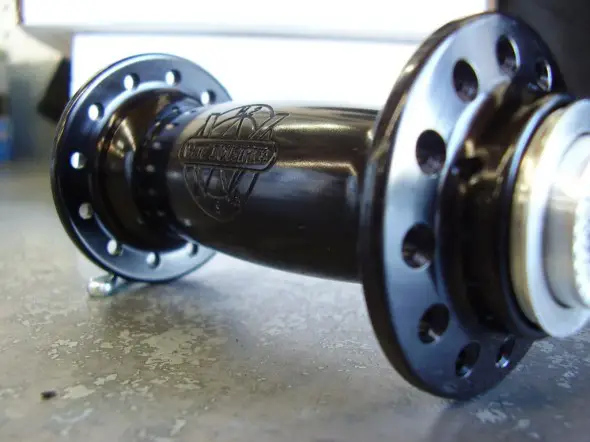

A preliminary assessment of the hubs had me eager and impatient to lace them up. The flanges are thick and the holes are drilled deeper into them. They are more than capable of accepting radial spoke lacing patterns. The end caps of the hubs, both front and rear, are heavily serrated to insure that when your quick releases are tightened, those hubs are not going to shift under ANY load. And on a purely cosmetic note, they don’t look like modern hubs. The middle of them balloons out, showing some girth as compared to many newer hubs which are very “dainty” in appearance.

I laced Sapim CX-Ray spokes with alloy nipples to Velocity Escape rims. 24 holes front, 28 in the rear. 2-cross lacing pattern in the front, and a 3-cross in the rear. At only 1400 grams for the entire wheelset, they are light, durable, and competitive. I am 6’1 and 170 lbs, smooth on a bike, but not easy on equipment. [Ed. Note: See “Is Joey OK?”] I demand a lot from what I ride.

I’m not the only one. Famous racer Jonathan Page has his White Industries Hubs laced to ENVE rims. Tim Johnson has had disc White Industries hubs laced to Zipps. Even the entire Raleigh/Clemente Cyclocross Team have theirs lased to FSA rims this season. Wheel builder Rob Curtis of PSIMET relies on White Industries hubs to yield a light, yet stout, wheel for his racing teams, and has hundreds of clients who ride a set of his custom made wheelsets.

Seven months and 2000 plus miles later, I hold the H2 and H3 hubset in high regard. Besides being some pretty jewelry that hangs off my bike, they have been problem-free; not a single thing has gone wrong. I did a 300 mile overhaul after the bearings were broken in and was unable to find a single contaminant in the freehub body or hub shell interface. I did another peek at the internals when mile 1200 and 2000 rolled around and it was still clean as could be. The rubber seal that bars dust and debris from entering its titanium freehub body is a simple O-ring and does not produce unnecessary friction as the hub is freewheeling. Other great aspects of these hubs are the titanium freehub body, which has yet to show any major signs or marring from the cassette under heavy loads. Unlike many hubs that compare at the same performance and weight level that have alloy bodies that mar within the first 1000 miles, the titanium body was very resilient, a plus on long-term usability, especially for cyclocross. Lastly, the bearings are your most commonly found 6902 and 6802 bearings. This makes any overhaul easy when you can quickly muster up these parts without hassle.

The bad: I was not a fan of the initial build process, as I would ideally like a hubset to have the same spoke lengths. I tried about 12 lacing patterns from radial to three cross, and various combinations of them. I couldn’t produce the same spoke lengths like I could with other hubs I have built up in the past. I used Sapim spokes and luckily I can order quantity and sizes relatively easily over the phone. Secondly, I found it a bit tedious to overhaul the hubs. They are a bit different as you do not use two 5mm hex keys to tighten or loosen the sealed bearings. Rather, you press them together while using three separate 2mm pins that tighten a collar. Not an easy way to tighten a hub, but the plus that comes out of this engineering design is that the hub will not develop play as you ride like most hubs that utilize the two 5mm hex keys. This is great for long term durability, especially if you like riding more than wrenching on your gear.

The new T11 rear hub recently introduced by White Industries has the same construction, quality and durability as the tested H3 rear hub. The only difference, as stated on White Industries web page, is that “T11 version is 9, 10, and 11 speed compatible. Neither the H2, nor any previous generation White Industries hub will work with 11 speed cassettes. The newest 11 speed system requires the largest cog to cantilever over the hub shell and our older hubs were not engineered based upon this design.”

These hubs are available directly from White Industries, from your local authorized White Industries dealer, or one of the many custom wheel-builders such as PSIMET.

Retail for the H2 front hub is $133.90

-Available in 16h, 18h, 20h, 24h, and 28h drillings

-Weight: 97 grams

Retail for the H3 rear hub is $272.95

-Available in 24h, 28h, 32h, and 36h drillings

-Weight: 252 grams (Shimano/Sram)