In 2019 I reviewed a Thesis OB1 bike. Thesis bike founder Randall Jacobs set out to offer a bike that covers more categories and allows riders to own one less bike. His timing could not be better. At the time gravel was a burgeoning category of bike riding, with more cyclists riding mixed terrain and discovering what cyclocross riders did in the off-season. The new popularity creates a new category of bike, just as mountain biking did in the 1990’s.

Jacobs is a bike industry veteran who at one point lived in Asia to manage the supply chain for bicycle brands. During that time, he learned Mandarin and befriended many in the production side of the Asian bicycle industry. It is through these relationships that he developed the Thesis OB1 bike of his design. Jacobs has continued success with Thesis Bikes.

Spinning off that success, Jacobs started Lōgōs Components where he seeks to design and offer components to upgrade your bike.

Why Wheels?

Logos Epoche 700C wheel. © C.Lee/ Cyclocross Magazine

Jacobs directed me to a podcast he did on the Gravel Ride podcast with Craig Dalton where he described his thoughts about creating wheels as Lōgōs’ first product. Jacobs is a co-host on the Gravel Ride podcast, so it comes across as a bit of an infomercial, but I found it interesting nonetheless.

Simply put, Lōgōs Components’ first product is wheels because, “after tires and fit, wheels generally offer the highest return on investment of any upgrade that can be made to a bicycle, and especially with gravel bikes, a second set can enable more types of terrain to be explored with the same bike,” according to Jacobs. Thesis Bike is quite successful with a one bike/two wheelset model, and Lōgōs builds on that.

Wheelsets for around USD 1000 is a competitive category. Jacobs feels that a higher quality product with durable, serviceable components is missing at this price point. Weight is fairly low on the priority list but the 1380-gram weight of a pair of 700C Epoché wheels, including tape and valve stems, is incredibly good.

Wheel Components

Jacobs told me hubs are a high point of failure for bicycle wheels. Literally the core of the wheel, hub failure renders the wheel useless and a projectile to the landfill. Bearing replacement is possible sometimes, but driver replacement is often not due to the incompatibility of components. Most hub drivers use a ratchet mechanism with spring-loaded pawls pushing against a toothed driver. Most commonly there are 3 pawls to share the load. If the hub driver is not precise, the load is not shared by all the pawls evenly, leading to premature failure.

One of the best-known alternatives to the simple pawl ratchet is the Star Ratchet mechanism that William Hugi of Switzerland introduced in 1995. DT Swiss continues to use the dual spring star ratchet mechanism with twin floating drive rings that has proven durable with toolless disassembly over the 3 1/2 decades since. The large engagement surface and twin floating drive ring design is forgiving to minor misalignment, contamination and wear that comes to any hub with regular use. This leads to high reliability. Over the years several other companies licensed the technology, but since the patent expired this is an “open standard.”

Just to note, only the DT Swiss 380 and 350 series continue with the dual spring version. Other DT Swiss hubs use a single spring EXP star ratchet, still under patent. The new design requires a tool for disassembly and has had some problems.

All of that is to say, Lōgōs uses the dual spring star ratchet with standard 36-tooth drive rings, yielding 10 degrees of engagement. Replacement drive rings are abundant and easily available. I verified that the parts are completely interchangeable with DT Swiss 380 hubs. The Lōgōs hub is upgradable for faster engagement, or slower and quieter, by changing the drive rings to easily obtainable 54-tooth or 18-tooth drive rings, respectively. Shimano HG-compatible 11-speed or SRAM XDr bodies are available. The hubs are through axle only (no 9mm QR) and compatible with center lock rotors. Continuing the reliability theme, the Logos wheels have Enduro bearings and use stainless steel Pillar Wing spokes with externally accessible brass nipples.

The logos hub is 100% parts compatible with a DT Swiss star ratchet hub. © C.Lee/ Cyclocross Magazine

700C, 650B, 29″

Lōgōs wheels are available with three different rims, all carbon. The 29″ mountain bike wheels have 4 more spokes, a X3 spoke pattern, and boost spacing. The 700C and 650B use the same hubs with 24 spokes laced X2. The rims differ by width as well as diameter.

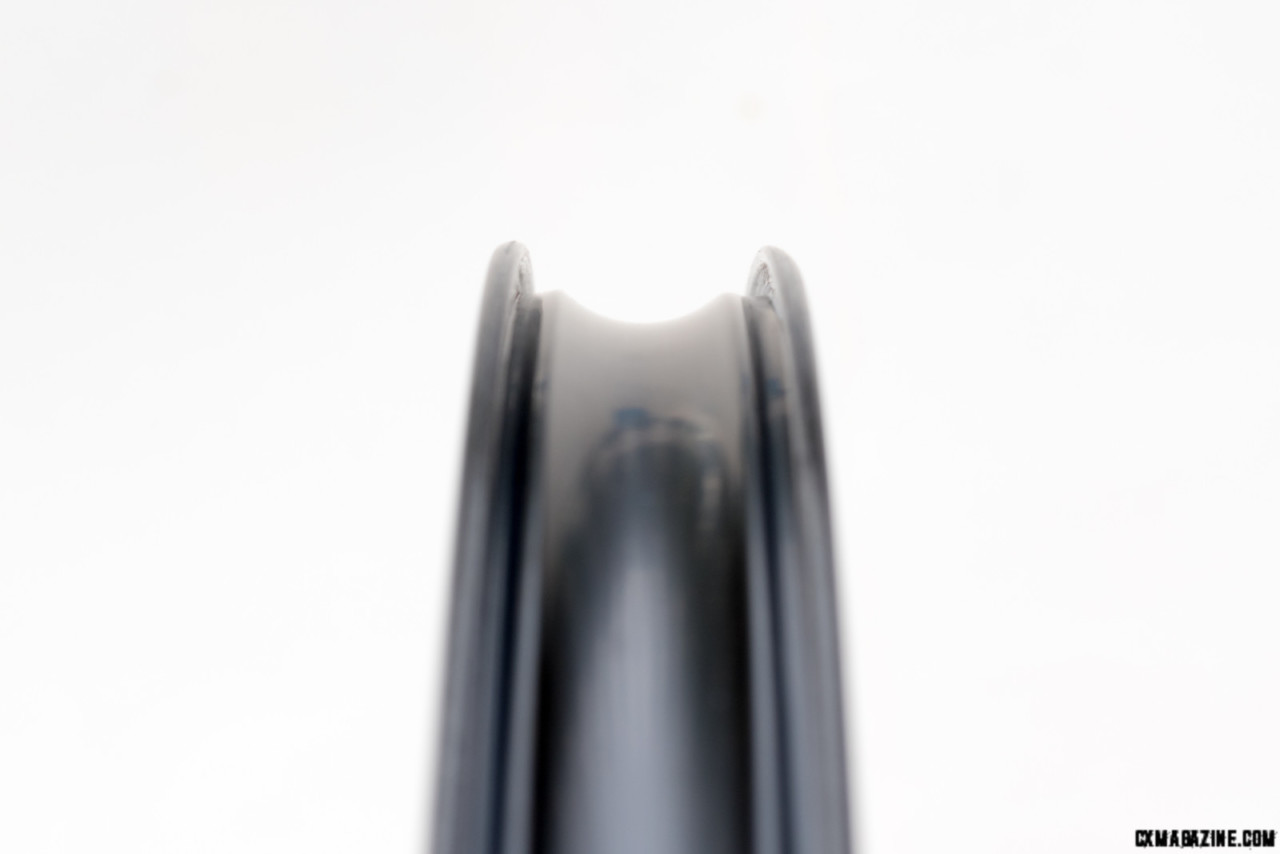

I rode the Epoché, the 700C version. The rim is 24mm wide internally with a hooked profile. The outside dimensions are 30mm deep and 32mm outside width. The Epoché is the only rim in the Lōgōs lineup with a hooked rim profile for reliable compatibility with tubeless road tires that run at higher pressure. The discussion endures, but for high-pressure applications, Jacobs and I agree that the industry standard is not yet tight enough (pun intended). A prominent bead shelf and a bead retaining ridge point to an easy burp-free tubeless setup. The recommended tire width for the Epoché is 28-54mm. Lōgōs achieves a low rim weight of 390 grams on the Epoché even with a molded-in bead hook using a polished mold yielding a smooth, raw carbon rim finish that does not require additional surface coating. Also, spoke hole reinforcement for reliability and long rim life is only applied at each spoke hole rather than reinforcing the entire circumference. This costlier process requires more drilling precision but saves additional rim weight.

The Lōgōs Epoché rim is 24mm wide internally with a hooked wall and a good bead retaining shelf. © C.Lee/ Cyclocross Magazine

Cross and Spokes

Pillar Racing Spokes is a Taiwan spoke brand that is on most OEM wheels spec’d out of that country. The company has been around for 30 years and the Pillar spokes have proven reliable. The Wing version is a bladed spoke. Bladed or flat-butted spokes not only have an aerodynamic advantage but also improved strength thanks to the grain alignment from forging the flat section. Another advantage is the ease of detecting wind-up during wheel building. If you have ever trued a tensioned wheel, thin gauge spokes wind up as the spoke and nipple thread interface faces more friction with increasing spoke tension. We used to mark the round spokes on one side to detect wind-up, but with a flat spoke section, not only is the wind-up easier to detect, but the spoke can also be held to avoid that.

The most common crossing pattern with modern carbon rim wheels is X2. That is, the spoke crosses 2 opposing spokes from the hub to the rim. When I learned wheel building many years ago, the common rim material was aluminum alloy. Due to the malleability of the rim, 32 or 36-spoke wheels were common, most commonly with a X3 or even X4 pattern. The spoke is interlaced with the opposing spoke at the crossing closest to the rim. Stiffer carbon rims allow lower spoke count and hence a reduced number of spoke crosses.

The Lōgōs Epoché has 24 spokes X2 and I immediately noticed the spokes do not interlace. Though they cross as usual, the opposing spokes never touch. Interlaced spokes may offer load sharing among the spokes, increasing lateral wheel rigidity and providing more clearance for the chain and pulleys on the rear drive side. These are theoretical benefits, and I could not find any verification of real-world advantages. Jacobs and I had a discussion about this since I’ve always built wheels with interlaced spokes. With modern wheel components such as the stiffer carbon rim and no verified advantage to interlacing spokes, Jacobs cited the benefits of not interlacing. There is no stress from the spokes bending at the cross, the spokes are quieter, the wheel is a bit easier to build, and perhaps the built wheels are more compliant. Lōgōs tested interlaced and non-interlaced spoke patterns and the unlaced design won for the Epoché. That may differ for other wheels in the Lōgōs wheel line-up according to Jacobs.

The offset of the rim’s spoke holes by 2.5mm reduces spoke tension asymmetry with a dished wheel, and only one spoke length is used for both sides of the wheel.

The spokes are not interlaced at any crossing on the Lōgōs Epoché wheels. © C.Lee/ Cyclocross Magazine

A more typical interlaced spoke crossing on a DT wheelset with a hub design similar to the Lōgōs Epoché. © C.Lee/ Cyclocross Magazine

Ride and Review

The Lōgōs Components Epoché comes taped with valve stems installed. All you need is a pair of tubeless tires and some sealant. The front wheel weighs 620 grams and the rear 760 grams with the tape and valve stems installed. The relatively lightweight 390-gram rim contributes to the lightness where it makes the most difference.

Out of the box, the wheels are true and round. I checked the spoke tension and it is even all around for each side respectively. I’ve had wheels with rotor or cassette spacing that is a bit off compared to the gamut of other wheels out there. Sometimes swapping wheelsets means a significant derailleur adjustment or caliper adjustment. A small turn of the barrel adjuster is not unexpected, but several turns is. Sometimes the problem is over-locknut width or worse, machining tolerance on the rotor mount. Caliper adjustment between wheelsets is not uncommon, but the Lōgōs Epoché samples easily hot-swap with some other name-brand wheels without any adjustment to either the derailleur or caliper.

The review set of Epoché wheels have a SRAM HDr driver, but I needed a Shimano HG 11-speed body. As a temporary measure, I pulled the cassette body off of a DT Swiss 380 hub. I also noted the Lōgōs endcap fit quite loosely. This is a frequent problem I have experienced with press-on through-axle endcaps on several brands, especially if the endcap is responsible for holding the cassette body on. In the field, the weight of the cassette will pull the whole body off. In the worst case, pawls will fall out into the dirt and be lost. In this case, the spring or a drive ring can slide off, or dirt can contaminate the system. The DT Swiss endcap fits significantly tighter, so I used that with the DT Swiss HG body for the majority of my rides. This easy exchange is a demonstration of the cross-compatibility that Jacobs wants. Lōgōs sent an HG body, but the accompanying endcap is still somewhat looser than its DT Swiss counterpart. All this said, this is not a problem at all when the wheel is on the bike, and a potential annoyance in the field if the rear wheel needs to be removed. Jacobs told me Lōgōs is looking for a better retention method.

I initially chose a 40mm gravel-size tire front and rear. The American Classic Wentworth 700C X 40 measures 95mm bead to bead. Set up is quite easy on the Lōgōs Epoché with a floor pump. The tires stretch to 39mm with 25 psi inflation. I rode this particular setup extensively in all conditions including two mid-season cyclocross masters races. Many of those rides included rocky roads and trails with buried rocks and roots. I rode without inserts and tire pressure between 19 and 25 psi depending on the anticipated terrain of my ride. Invariably there are times when the pressure is too low for the terrain, leading to tire collapse, bottoming out onto the rim. Even in these instances, the tire bead of this combination did not unseat, nor did I experience any burps. The Epoché rims sustained no damage, the wheel remains true and the spokes maintain even tension.

Lōgōs Epoché 700C wheels with American Classic Wentworth 40mm tire

I also used a 32mm WTB CrossWolf for some riding. Lōgōs recommend tires from 30mm to 54mm wide. The 32mm CrossWolf expands to 33mm and is barely wider than the 32mm outside width of the Epoché rim. The wide rim puts more of the narrow tire tread on the ground since the sidewalls are more straight, effectively squaring the tire off. I zipped around my cyclocross practice course which has very few rocks, so rim protection was not a concern that it is on a rock-strewn trail.

This shot shows a 32mm tire is almost the same width as the outisde width of the Logos Epoche rim.

The Epoché is a versatile wheel that can fit a 28mm road tire, has a maximum tire pressure rating of 110 psi that is much higher than needed for most applications, yet can hold a huge gravel tire at low tire pressure. With a 28-30mm tire, the Epoché rim meets the 105% rule for bicycle wheel aerodynamics, and there is the mechanical security of a bead hook to keep the tire on with high inflation pressure.

Hard cornering and sprinting places lateral force on the wheel that makes the rim want to deflect away from the centerline. Spoke tension (along with rim rigidity to a degree) resists this force, so the spokes on one side gain more tension while the other side slackens. In a wheel with high spoke tension, the spokes and rim should stay relatively stationary regarding the centerline of the wheel. If the wheel deflects when leaning into a corner or when sprinting, the bike will change its path. The adverse effect on steering is unnerving to the rider, and in the worst case will cause a crash.

The Lōgōs Epoché wheels exhibited none of that behavior. Riding with low tire pressure already has tire squirm, so to evaluate cornering with the Lōgōs Epoché, I used the American Classic Wentworth with its even tread and round profile, and pumped it up to 40 psi which seems rock hard for a tire that size. On dry pavement, the big tire sticks like glue when leaned over and the wheel keeps the bike on line like it’s on rails to borrow a cliché.

Verdict

You have to decide what you want in a wheel. Many wheelsets in the 900-1200 USD mid-price point perform well out of the box. An example is the Hunt 35 Carbon Gravel X Wide, and others exist. What you get with the Lōgōs Epoché wheelset is significantly lighter, has very thoughtful design details with star ratchet hub durability and re-buildability on top of excellent out-of-the-box performance. Lōgōs has a lifetime warranty against manufacturing defects and a lifetime incident protection policy. If you are looking for a new 700C wheelset for road or gravel, I recommend the Lōgōs Epoché. The wheels are warehoused in the U.S. for fast delivery, and the company is building a dealer network in the U.S.

Lōgōs Epoché 700C Wheelset Specs

Weight: 620 grams front, 760grams rear (Shimano), 1380g pair w/tape and valve stems

Rim: Asymmetric carbon rim, 390 grams, 30mm deep, 24mm internal width with hooked wall, 32mm external

Spokes: 24 bladed spokes x2 f/r

Axle: 12X100mm front, 12X142mm rear

Freehub: Shimano HG and SRAM XDR driver available.

MSRP: $1248 USD

More info: logoscomponents.com