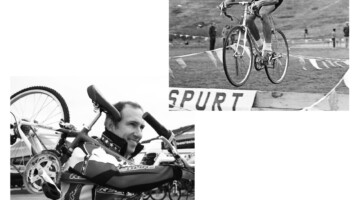

Gengler started NFG two years ago, and already he’s constantly busy with frame-building and repairs. © Molly Hurford

by Molly Hurford

One of the best perks of moving to Easthampton, Massachusetts may have been that National Champion Jeremy Powers is now practically living next door. But there are other perks, too, and one of the biggest is that NFG Cycles, a small custom framebuilding company run by Niall Gengler, is literally across the street from my new house. Of course, that meant that immediately after moving in, I was already out and about, prowling through Gengler’s shop, asking a million questions about his frames. Gengler hasn’t been in the business for too long, but he’s been in framebuilding for a while with other small independent companies, and told me he’s wanted to build bikes for as long as he can remember. He’s been doing well too, and recently began branching into cyclocross bikes, starting with his own for last season.

As I prowled around the shop, I asked where he got his start. “My dad was always super mechanical so I was always taking things apart and putting them back together,” he told me.

However, Gengler didn’t originally plan to go to school for such a practical skill. “My plan was to go to art school,” he says, but when he went to see what the Hampshire College had on offer in their art program, he wasn’t excited. But when he found the machining shop during orientation, he found the program he wanted. He asked, “If I went to school here, could I, in theory … build bicycles?” They said yes, and Gengler was sold.

Now out of school and on his own for a few years, his studio is in Eastworks in Easthampton, a large brick factory building that’s been repurposed as a studio space (Gengler is situated between a blacksmith and a guitar repair studio) and a more artistic shopping center, complete with uber-hip salons and furniture shops.

“I just wanted to do it so bad. I had to make it happen somehow, and now it’s stabilized a bit. For a solid year and a half, there were solid 80-hour weeks of pulling my hair out. Now I’m not doing crazy hours all the time, though I pull plenty of 15 hour days.”

His bikes are almost entirely thin-wall steel, though he’s dabbled in titanium. And all are completely custom, without any “off-the-shelf” parts. “With each customer, I totally start from scratch.”

So, say I walk into his shop and ask for a custom cyclocross bike. What happens next?

“I try to get in their domes and pull out what they want,” he said. Gengler is a firm believer in building what his customer wants, whether he or she is even aware of what that is.