by Clifford Lee

When Kettle Cycles’ launched their Kickstarter project with the goal of creating a carbon-ceramic composite disc brake rotor, cyclocross tech geeks had a field day. After all, with the launch of disc brakes on all levels of bikes this past season, from Jeremy Powers’ Focus to even bargain-priced rigs, it’s clear that discs are here to stay in cyclocross, and the technology has just begun to evolve. We got our hands on a set of the rotors, and will be conducting a full review, but for now, enjoy our initial impressions:

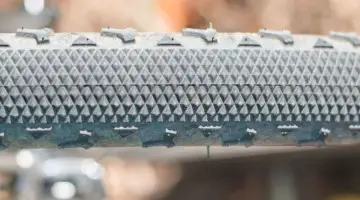

Kettle Cycles is a small company in Illinois dedicated to providing components that improve the cycling experience. The Super Feather Light (SFL) disc rotor is a one-piece rotor that is made in the USA from a silicon carbide carbon ceramic matrix (SiCCC), that creates, in Kettle Cycles’ words, “more reliable, better wearing, lighter weight brake rotor. It uses silicon carbide for friction, ceramic for heat, and carbon fiber for strength.”

Initial production began with crowd-funding through Kickstarter, and delivery of the SFL one-piece rotor came at the beginning of 2013, with a less expensive, albeit heavier, two-piece version soon on the way. The rotors under evaluation were a reward for financially backing the project that I feel has a lot of promise.

The SFL rotors are indeed light, saving 43 grams over the already lightened Avid HS1 steel rotors (that come with the Avid BB7 SL brakes) in the 160mm size, and 35 grams in the 140mm size. Compared to standard (not HS1) steel rotors, like the ones that come with the Avid BB7, the weight savings could be as much as 110 grams total, or a quarter pound of weight savings. However, that weight is hub-centric and there’s more than just weight savings to be had. If Kettle Cycles’ claims are true, thermal capacity, conductivity, and emissivity are better than standard metallic rotors, leading to better brake performance when the competition heats up. No warping, minimal heat transfer to other brake components, and faster cooling are some of the claimed qualities of the new composite. Given the problems seen with carbon braking surfaces on rims, those are big claims, but I’m not a composite engineer. Carbon rims are not made from the same composite, lacking the silicon carbide and ceramic components of the rotors. This sounds like just what the brake industry has been looking for, especially as disc brakes are being adopted in the bike industry beyond mountain bikes. At the very least, they are what weight weenies are looking for to offset the inherent weight penalty of disc calipers, rotors and hubs compared to cantilever brakes.

A video posted demonstrates a metal disc rotor being cut with an angle grinder, with a SiCCC SFL rotor as the cutting blade! So they cut well, but do they help slow you down?

There is a burn-in process, not that dissimilar to burning in new metallic rotors or new pads, and once a new surface film is created, the rotors are ready to perform. After mounting the new rotors, I was anxious to complete the burn-in process and see how they felt.

Kettle Cycles has tested its rotors with several brake pads and has recommendations on their website. I mounted the rotors to a bike with Avid BB7’s: one with Avid metallic pads and the other with Avid resin/organic pads. The burn-in process was much faster and smoother with the metallic pads. The resin/organic pads took a long time to burn in evenly and never produced the same stopping power of the metallic pads. Sure enough, the Kettle Cycles website indicated that Avid resin/organic pads will likely need to be replaced with other pads for optimal brake performance with the SiCCC rotors. I swapped the resin/organic pads with KoolStop semi-metallic pads and found them an improvement, but still not stellar.

So far, even after the initial burn in and a couple of days’ riding, I have not yet experienced anything close to the same stopping power of metal rotors. They modulate well, but require significantly more lever pressure to stop with the mechanical disc brake calipers. If you’ve moved to disc brakes for their stopping power (as opposed to mud clearance benefits), you might be disappointed by their initial performance. I also hear more brake squeal than I do with metal rotors in dry conditions, but I have yet to try it in wet conditions. Certainly, these are only my initial impressions after a few weeks of use, and my long-term performance assessment may be different. Perhaps I still need to further burn the rotors in.

One potential advantage of these carbon rotors isn’t related to weight savings, heat resistance or braking power but the fact that the rotors are without cut-outs. When it gets muddy, wet and gritty, I hope to see whether the lack of grit-collecting cut-outs as seen on metal rotors will result in better brake pad life. As we’ve reported earlier, in early December 2012, at a wet CCCX race in Manzanita Park, publisher Andrew Yee, and local fast Masters Don Myrah and Justin Robinson blew through disc brake pads (brand new Avid BB7 pads, and Formula R1) in just a handful of laps, but all were running metal rotors with cut-outs. Others reported similar problems on certain days at the 2013 Cyclocross National Championships in Verona, WI. Will a solid rotor make a dramatic difference in pad life? We’ll see. Let’s hope Mother Nature cooperates to give us some spring cyclocross conditions. Otherwise I’ll have to head to the beach and get creative with some wet sand.

Stay tuned as we continue to put the Kettle Cycles SiCCC SFL rotors through the paces.

Specs:

- $99 140mm, $124 160mm

- Silicon carbide/carbon fiber/ceramic composite

- 140mm rotor, one piece 6 bolt version

- 45 grams

- 160mm rotor, one piece 6 bolt version

- 53 grams

- More info: Kettle Cycles